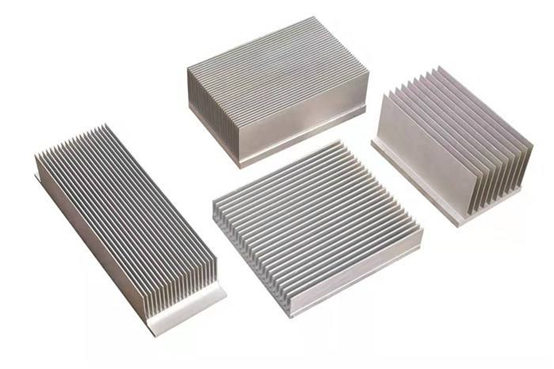

Aluminum heat sinks are widely used on electronic equipment. The most primitive ways of producing air-cooled heat sinks are extrusion and casting. However, the current technique of either extrusion or casting limits the fin ratio of heat sinks (the fin height compared to the space between fins). While casting can only make rather rough and large blocks of heat sink, extrusion can make fins with 5:1 to 8:1 ratio. However, it is still less than adequate for the equipment with high power, such as components for 5G equipment, which requires at least 12:1 fins and larger contact base.

Previously, the solution is to bond fins by welding or slotting, but the productivity is too low and costs are too high for mass application,where there is limitation for the sizes of the heat sinks too. Besides, since the fins and base are not an entire metal body, there is still problems with the circulation efficiency and part firmness.

A new technique, ‘skiving’, was developed recently. The particular machine can slice fins evenly and precisely from an aluminum (or brass) block and forms the required high-ratio heat sink automatically (the ratio can be easily over 100:1). All the previous problems were thereby addressed perfectly. The fins can even be skived into flat or wave shapes, offering more options for different applications.